CHF 1,836.00

CHF 1,836.00

excl. VAT

Not Available

This combination does not exist.

Units of Measure: Units

Add to basket

Warranty conditions

12 months manufacturer's warranty from date of delivery.

The warranty expires if,

- The installation is not carried out by a qualified professional.

- The pump is opened or otherwise tampered with.

- If the wrong or contaminated operating materials are used.

The LT-Shop does not assume any assembly and disassembly costs.

Product information:

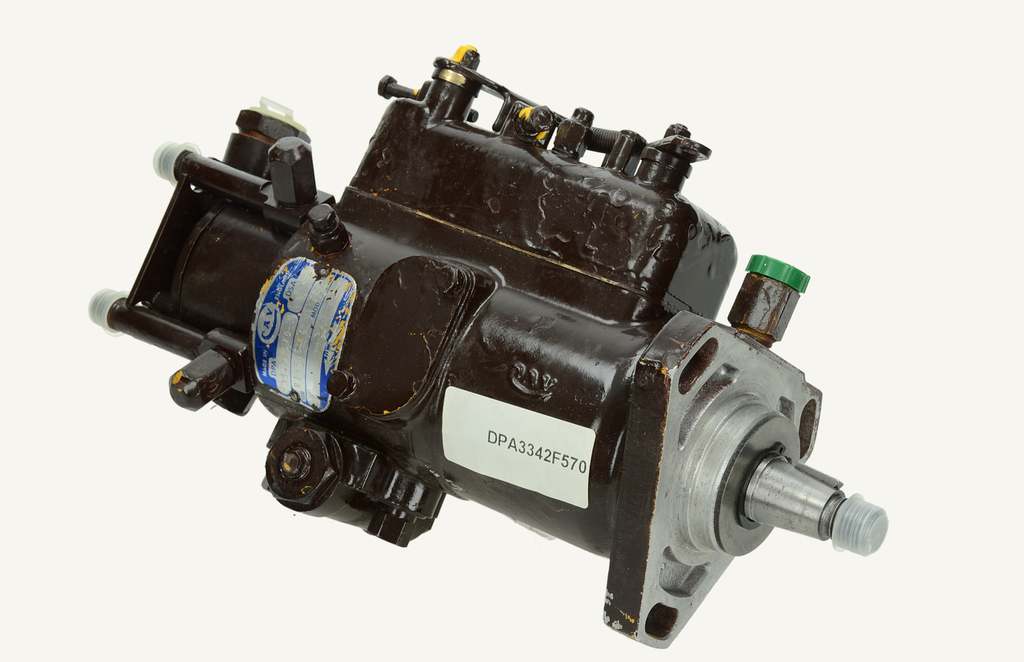

DPA3342F570 suitable for 8045.04 engines

Injection volume 51cm³

Injection pump removal :

Clean the outside of the engine and injection system!

-1 Cylinder (for water pump) Set working stroke.

Turn engine back 30°.

Remove the small cover at the rear of the flywheel on the left (M8).

Turn the engine by hand in the direction of rotation until the IGN CAV mark is exactly in line with the indicator plate.

(Attention there are also flywheels which have been stamped with IGN Bosch, select the correct marking depending on the pump brand)

Remove injection lines to and return, throttle and shut-off rods, as well as 3 fastening screws of the pump

Dismantle the front cover opposite the injection pump.

Loosen the centre nut. Pay attention to marking gear 4-4 !

The special nut also acts as a trigger to push the gear wheel off the cone.

The pump can now be pulled out to the rear.

Injection pump installation:

Start of delivery Check the setting on the CAV distributor pump (DPA) injection pump before installation

-Dismantle the side cover on the injection pump

-Connect the line of the nozzle tester to the 1 cylinder of the injection pump Build up a pressure of max. 20-30 bar and slowly turn the pump in the direction of rotation (arrow) until a high resistance can be felt.

Caution: Some versions have a pressure valve built into the line fitting, which must be removed for the check.

The edge of the circlip can be checked in this position with the corresponding letter on the rotor and adjusted if necessary.

Start of injection = letter W or X must correspond exactly with the ground edge of the circlip.

Fiat 3 cylinder=W

Fiat 4 cylinder=X

Check whether the engine flywheel marking is still at IGN.

Check gearwheel 4-4 .

Injection pump with key on gear wheel discs .

If everything is set correctly, the wedge of the pump matches the gear wheel.

Tighten hexagon nut to 81 Nm.

Turn the pump so that the ground circlip edge is exactly in line with the letter

W or X .

Should correspond plus -minus with the old marking on the spur gear cover

Tighten the three nuts on the injection pump to 25 Nm.

Turn the engine back approx. 30° and slowly turn to IGN, check the edge of the circlip in the pump.

in the pump .

Install injection lines, supply and return lines, switch-off and throttle control.

Bleed the system! (Turn the engine with the injection lines open at the top of the injection nozzles with the starter (full throttle) until bubble-free fuel comes out of the lines).

Tighten the lines Start and test run.

Start of delivery

Fiat 466=17°+/-1° CAV DPA3233F420

Fiat 566=13°+/-1° CAV DPA3233F700

Fiat 666=15°+/-1° CAV DPA3342F470

Fiat 766=18°+/-1° CAV DPA3342F570

Injection sequence

466=1-2-3

566=1-2-3

666=1-3-4-2

766=1-3-4-2

Nozzle insert 466,566,666,766 = BDLL140S6655 Nozzle opening pressure 225-235bar

Turn pump in direction of arrow=later start of injection !

Checkout