CHF 2,320.00

CHF 2,320.00

excl. VAT

Available: 1.0 Units

This combination does not exist.

Units of Measure: Units

Add to basket

Product information:

Attention:

The specification in the workshop manual 1.35mm is incorrect!

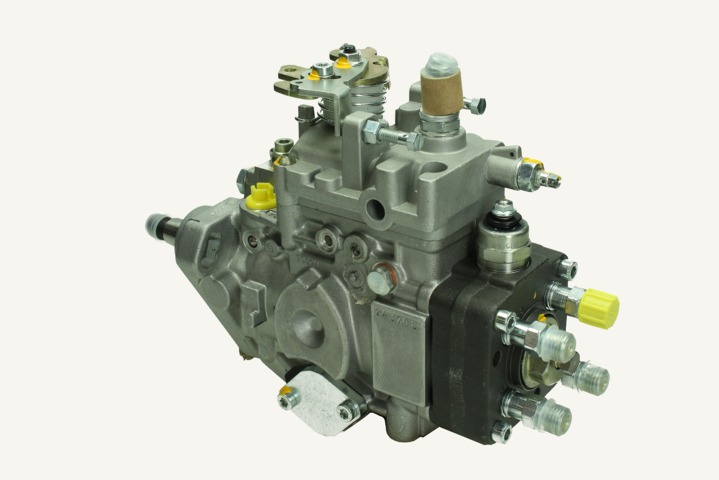

The correct setting is 1.00mm

Tightening torques:

Injection pump blocking screw M10 2.7Nm

Gear wheel fastening nut 95Nm

IMPORTANT: Engine speed fluctuations at low engine speed are not recognised or perceived as a problem by all drivers.

If the tractor problem is an engine speed fluctuation or a fluctuation of less than 50 rpm with the engine at low idle (800 to 1300 rpm), go to step 14. Fluctuation of less than 50 rpm .

If the engine speed fluctuation or low idle fluctuation is greater than 100 rpm, the cause can be found by checking the following steps 1 to 13.

1. check the entire fuel supply line for obstructions. This can be done in many different ways. The quickest and most accurate method is to install a low pressure gauge on the banjo bolt at the inlet of the injection pump.

- There must always be positive pressure at this point. Approximately 0.41 to 0.69 bar at full throttle.

- If the gauge reads 0 at full throttle, the problem is on the fuel supply side of the system.

2. check the fuel supply for contamination. Run a short line from a clean container to the fuel feed pump

- Run the tractor on this supply and compare the engine running.

3. check the high (2750 rpm) and low (800 rpm) idle settings.

- Make sure that the nuts secured against tampering are locked again after adjustment

4 Check the air intake for obstructions.

5. remove the thermostart and check for fuel leaks

6. check the banjo bolts on the injection pump inlet and the return lines to ensure that they are correctly installed.

- The banjo bolt with the small opening hole must be installed in the return line connection.

7. make sure that the pointer in the flywheel adjustment cover hole is correct and points to PMS on the flywheel (PMS stands for top dead centre). True top dead centre of the engine can be achieved by:

- Removing the fuel injector in cylinder number one (front).

- Remove the flywheel adjustment hole cover and rotate the flywheel until you see PMS (represents top dead centre) at the end of the pointer.

- Install a dial indicator with a magnetic base with a shaft long enough to reach the top of the piston over the number one injector hole.

- Turn the engine backwards a few degrees to move the piston away from the dial indicator.

- Then turn the engine forwards to bring the piston up towards the dial gauge.

- When the dial indicator needle stops moving, continue turning the motor until the dial indicator needle starts moving again.

- Half the distance between the point where the needle stops moving up and the point where it starts moving down is the true top dead centre for piston number one.

- When the engine is turned to this point, the pointer in the flywheel adjustment hole cover should point directly to PMS (representing top dead centre).

- If it does not point directly to PMS, bend the pointer carefully so that it points to PMS. If the pointer is bent out of position, it will cause an error when checking the setting in step 8.

8. make sure that the injection start of the fuel injection pump corresponds to the technical data.

The dial gauge kit can be rented from LT 99395603-MIETE

9. remove the four injection nozzles and check the injection pressure and the injection pattern. 10. remove the fuel injection pump.

10. remove the fuel injection pump and the injectors. Have them checked by an authorised Robert Bosch Service Centre.

- Explain the engine problem in detail to the service centre personnel servicing the fuel injection pump and ask that the pump be completely disassembled and all components checked. This applies in particular to the governor springs, low-load governor springs, governor pivot points, flyweights, measuring sleeve and associated parts.

- Injection pumps and injection nozzles must always be checked together as a set. 11.

11. remove the valve cover and check the valve clearance (on 0.30mm off 0.55mm)

12. remove each injector and carry out a compression test for each cylinder. Minimum compression is 20 bar The change from cylinder to cylinder must not be more than 3.4 bar.

13 After all checks have been performed and the engine is still fluctuating at less than 50 rpm at low idle (800 - 1300 rpm), proceed as follows:

14. if the tractor is part of a dealer's inventory, do not invest time or money in overhauling or replacing the engine.

- The symptom is caused by changes in engine tolerances during engine reassembly.

- Similar symptoms or problems may also occur with a replacement engine.

- The symptom (50 rpm fluctuation) does NOT occur above 1300 rpm and does not occur above 1000 rpm on most tractors.

- At the moment only TL90 tractors have been reported with the problem. The symptom (50 rpm fluctuation) can be detected visually (tachometer needle) or by touch (vibration).

- The problem has not been reported on the TL100 and TL80. The symptom is audible, but not associated with speed fluctuation or vibration.

Checkout