CHF 295.40

CHF 295.40

excl. VAT

Available: 2.0 Units

This combination does not exist.

Units of Measure: Units

Add to basket

Product information:

Caution:

The hole for the piston return spring has not been machined deep enough.

If excessive, continuous pressure is applied to the brake discs, especially during road transport, premature wear may occur on the brake discs.

Check the depth of the hole (12.5 mm) that accepts the piston return spring (part number 5120761). If the hole has been machined incorrectly, you must either drill out to the design depth of 12.5 mm or add spacer discs to obtain the correct depth.

The hydraulic filter is inhibited with brake disc wear. Excessive prolonged pressure on the brake disc can cause the friction material to separate from the disc.

If excessive, prolonged pressure is applied to the brake discs, especially during road transport, premature wear of the brake discs can occur.

When replacing worn brake discs, it is recommended to check the following:

That the three holes housing the brake piston return springs are correct. If a hole is found to be drilled incorrectly, either drill it further or add shims to achieve the correct design depth of 12.5 mm. The 12.5mm should be measured from the machined brake surface from the disc.

That the three anti-rotation pins of the brake pistons protrude 9.5 mm from the machined surface of the rear axle housing.

The springs are designed to exert gentle pressure on the friction discs via the brake piston. This ensures that the brake pedal travel is not too long. If the springs are not positioned correctly, the brake pistons will be pushed back into the gearbox housing by the rotation of the friction discs. As a result, the pedal would almost reach the floor when the brake is first applied before any brake pedal resistance could be felt.

Note:

The return springs 5120761 and the pins are only fitted to tractor models 120 - 155.

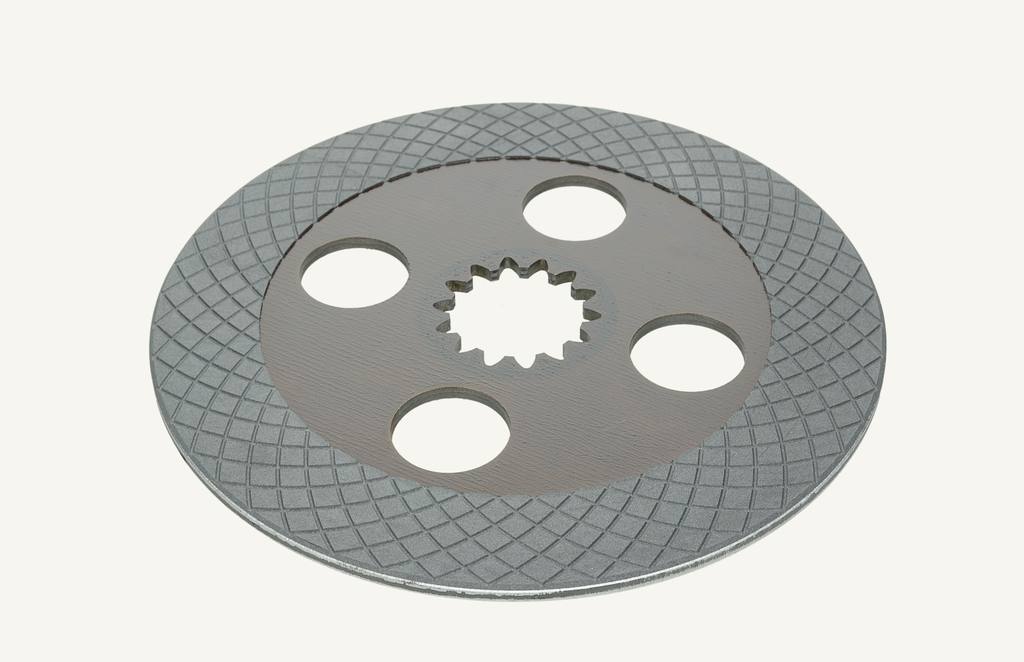

When replacing the brake discs, it is recommended that the latest Kevlar discs are used.

Install the latest brake discs with a Kevlar friction surface

Loud braking noise (banging, rattling, screeching or squealing)

Premature wear of the brake discs.

Heavy brake application and the heat of the rear axle oil lead to destruction of the adhesive in the brake disc friction material.

The type of brake material used tends to squeal on machines that are driven a lot on roads and therefore have higher rear axle oil temperatures.

Brake discs with Kevlar friction surfaces are now available from the spare parts department.

The Kevlar brake discs have been introduced into production from the following serial number: -

TM 120 - 155 ACM199748 New Kevlar brake discs 47126359 (old 5154521 Organic)

TM 170 - 190 ACM198908 New Kevlar brake discs 47126358 (old 5199927 organic)

Checkout